CNC Turning – Matel and Plastic Parts machining services

One of the fastest cnc turning service manufacturers in Turkey, complete prototype manufacturing and mass production and delivery with 3 working days to Europe 5 days America. For mass production and delivery, we are equipped with more than 20 lathes of various types, just to meet needs of precision turning parts. Choose suitable, fast and stable CNC turning to produce high-precision and high-quality CNC turning parts for you.

Send us your CAD or 3D files, our professional team will provide you with free review, drawing optimization, quotation and DFM within a day.

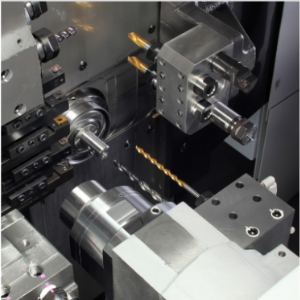

Automatic Swiss Type

CNC turned parts

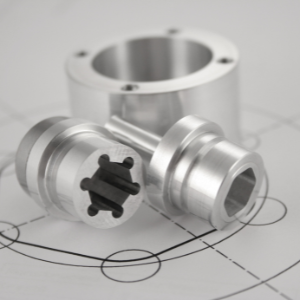

CNC Turned parts

The working principle of CNC Turning Machine

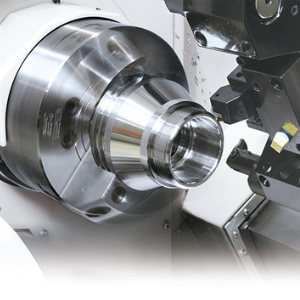

CNC turning is one of the central methods of manufacturing. It can produce cylindrical parts with various contours.

CNC turning is one of Zümre Makina’s many CNC services that is regularly requested for a specific type of product. Turning is a CNC machining method that involves rotating a workpiece in a chuck at a high speed. The cutting tool does not revolve like it does in CNC milling.u

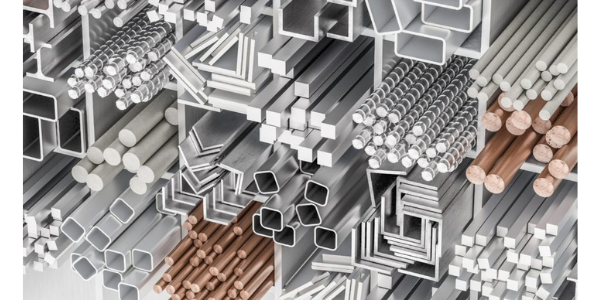

Aluminum, magnesium, steel, stainless steel, brass, copper, bronze, titanium, and nickel alloys, as well as nylon, polycarbonate, ABS, POM, PP, PMMA, PTFE, PEI, and PEEK, can all be turned. Lathe machines are another name for CNC turning machines.

Advantages of CNC turning.

1. Cylindrical parts

CNC turning machines are excellent for producing round or cylindrical items. These parts are made on lathes, which are rapid, accurate, and repeatable.

2. Processes available

CNC turning can be used for a range of cuts, including drilling, boring, threading, and knurling, even though it is typically employed for pieces of a specific shape.

3. High-quality workmanship

Visit our CNC machining services page to learn more about the overall benefits of CNC machining with Zümre Makina

What is CNC turning, and how does it work?

CNC turning is a type of precision machining in which a cutter removes material from a rotating workpiece by making contact with it. Computer instructions govern the movement of the machines, providing for exceptional precision and repeatability.

Turning differs from CNC milling in that the cutting tool rotates and is aimed towards the workpiece, which is normally stationary, from several angles. CNC turning is commonly used to generate round or tubular shapes since it requires rotating the workpiece in a chuck, resulting in significantly more accurate rounded surfaces than CNC milling or other procedures.

A turret holds the tooling that is used with a CNC lathe machine. This component is set up to perform specific movements and remove material from raw materials until the desired 3D model is created.

CNC turning, like CNC milling, can be used to produce prototypes and end-use parts quickly.

How to choose materials and compare with national standards of various countries, so as to find precision cnc turning parts suppliers, or to facilitate communication during design?

We have prepared 40 kinds of material inventory in our partner companies warehouses to ensure that customers’ prototypes and small batch precision machining parts and mass production are completed within 24 hours.Some of our materials are approved by IMDS.

CNC Turning for Metal Parts

CNC Turning Plastic Parts

Zümre Makina’s services include aluminum machining, but CNC turning can also be used to process metals such as magnesium, steel, stainless steel, brass, copper, bronze, titanium, and nickel alloy.

Mechanical and aspect components, which are frequently composed of aluminum, the most machinable metal, are frequently CNC turned. Aluminum parts can be produced with great strength, precision, and a superior surface polish.

While precision machining is most commonly associated with metals, Zümre Makina may also offer CNC turning services for plastic items. Nylon, polycarbonate, ABS, POM, PP, PMMA, PTFE, PEI, and PEEK are among the materials available for CNC turning, which provide more accurate parts than 3D printing.

| Material properties | Material model | American Standard (ASTM) | German standard (DIN) | Japanese Standard (JIS) | Chinese Standard (GB) | British Standard(BS) |

|---|---|---|---|---|---|---|

| Aluminum | Aluminum6061 | 6061 | AlMglSiCu | A6061 | LD30 | H20 |

| Aluminum7075 | 7075 | AlZnMgCu1.5 | A7075 | LC9 | L95 | |

| Aluminum2014 | 2014 | AlCuSiMg | A2014 | LD10 | 2014 | |

| Aluminum2024 | 2024 | AlCuMg2 | A2024 | LY12 | GB-24S | |

| Aluminum5052 | 5052 | AlMglSi0.5 | A5052 | LD31 | H19 | |

| Aluminum6063 | 6063 | ALMg2.5 | A6063 | LF2 | NS4 | |

| Aluminum1060 | 1060 | – | A1060 | L2 | – | |

| Aluminum1070 | 1070 | A199.7 | A1070 | L1 | – | |

| Aluminum1080 | 1080 | A199.8 | A1080 | LG1 | 1A | |

| Stainless steel | Stainless steel 304L | 304L | X2CrNi19-11 | SUS304L | 022Cr19Ni10 | 403S17 |

| Stainless steel 316L | 316L | X7Cr14 | SUS316L | 022Cr17Ni12Mo2 | 416S21 | |

| Stainless steel 301 | 301 | X5CrNi17-7 | SUS301 | 12Cr17Ni7 | – | |

| Stainless steel 304 | 304 | X5CrNi18-10 | SUS304 | 06Cr19Ni10 | – | |

| tainless steel 430 | 430 | X6Cr17 | SUS430 | 10Cr17 | – | |

| Brass | CuZn38Pb2 | C37700 | CuZn39Pb2 | C3771 | HPb59-1 | CW612N |

| CuZn39Pb3 | C38500 | CuZn39Pb3 | C3603 | HPb58 | CW614N | |

| CuZn36Pb3 | C38600 | CuZn36Pb3 | C3601 | HPb63 | CW603N | |

| Copper | C10200 | OF-Cu | C1020 | T1 | C101 | |

| C11000 | SE-Cu | C1100 | T1 | C101 | ||

| Steel | Mild steel 1015 | 1015 | C15 | S15C | 15 | 095M15 |

| Mild steel 1045 | 1045 | C45 | S45C | 45 | 080M46 | |

| Mild steel 1020 | 1020 | C22 | S20C | 20 | 050A20 | |

| Titanium | Titanium Grade 1 | GR1 | – | TP270 | TA1 | – |

| Titanium Grade 2 | GR2 | – | TP340 | TA2 | – | |

| Titanium Grade 4 | GR4 | – | TP550 | TA4 | – | |

| Plastic | PTFE | PTFE | PTFE | PTFE | PTFE | PTFE |

| PEEK | PEEK | PEEK | PEEK | PEEK | PEEK | |

| NYLON | NYLON | NYLON | NYLON | NYLON | NYLON |

How do we make every precision CNC turned parts have a consistent quality during the production process?

Claim | Quality record |

DFM identifies key dimensions | DFM report |

Reduce customer drawing tolerances and issue in-plant engineering | Drawings |

Identify key size | Procedur esheet |

| First article inspection before delivery | First record |

| Line inspection during production | Inspectio record |

Process CPK control | SPC report |

Sampling inspection of products in process | Shipmentin spection record |

Shipment inspection | Full size report |

Reliability test | Material proof |

Environmental protection requirements guarantee | ROHS report |

How do we make every precision CNC turned parts have a consistent quality during the production process?

With our partner companies, we can get your CNC machiend parts surface finished.

| Part material | Surface treatment method | Principle details | Function and standard |

|---|---|---|---|

| Aluminum | Clean Anodized | Anodizing can enhance the wear and corrosion resistance of the surface of the precision CNC machining part, and increase the surface hardness. | Hardness can reach 5UM-60UM |

| Color Anodized | Rich colors increase brand value | According to customer requirements, multi-color effects can be produced | |

| Powder Coating | Perform color matching according to Pantone and labor color card ral9016. | High temperature resistance, wear resistance and additional force | |

| Bead blasted | Guarantee the statistical precision CNC machining parts surface effect,Can be implemented in accordance with Apple’s surface grade requirements. | According to SSPC—SP7 level execution | |

| Brushing | Use the surface to maintain uniform rules and beautiful lines. | Can reach between Ra1.2UM-Ra40UM | |

| Polishing | Use a grinding wheel or cloth wheel and wax to remove to maintain the surface finish. | Can reach between Ra1.2UM-Ra40UM | |

| Stainless steel | Polishing | Use a grinding wheel or cloth wheel and wax to remove to maintain the surface finish. | Can reach between Ra0.6UM-Ra1.6UM |

| Passivating Sandblasting | The effect of passivated fine sand, the surface has corrosion resistance. | According to SSPC—SP7 level execution | |

PVD | CrN. TiN. TiAlCN. TiCN. TiAlN, etc. are plated on the surface to make the surface clear and beautiful. | Abrasion resistance, high cleanliness | |

| Steel | Polishing | Use a grinding wheel or cloth wheel and wax to remove to maintain the surface finish. | Can reach between Ra0.6UM-Ra1.6UM |

| Polishing, Plating Nickel/Chrome/Zinc | The process of using electrolysis to attach a metal film to the surface of metal or other materials to prevent metal oxidation (such as rust), improve wear resistance, electrical conductivity, light reflectivity, corrosion resistance (copper sulfate, etc.) and Enhance beauty and other functions. | According to ASTM B578-1987 (R2015) standard | |

| Heat treatment | Metal heat treatment is a process that heats, heats, and cools a metal precision CNC machining in a certain medium, and controls its performance by changing the surface or internal structure of the metal material. | According to the standard BAC5617 execution | |

| Powder coated | The spraying effect of powder spraying is in terms of mechanical strength, adhesion, corrosion resistance, aging resistance, etc. | Standard Guide for Testing Coating Powders and Powder Coatings in accordance with ASTM D 3451-2006 | |

| Brass | Plating Nickel | There are two processes of electroless nickel plating and electrolytic nickel plating, one is for conductive, the other is for decorative protection. | 1. Improve anti-corrosion fatigue life. 2. Improve the service life of wear |

| Chrome | The process of using electrolysis to attach a metal custom CNC machining parts film to the surface of a metal or other material. | Improve precision CNC machining parts wear resistance, reflectivity, corrosion resistance (copper sulfate, etc.) and enhance aesthetics | |

| Zinc | The purpose of cold galvanizing is mainly to prevent rust, and hot galvanizing has high anti-corrosion and anti-rust effect. | ASTM B695-2000 and military C-81562 mechanical galvanizing technical standards | |

| PVD | Before the copper is used for PVD, we must first polish and chrome the copper, and then perform PVD, the effect is even more beautiful than the ordinary electroplated surface. | Wear-resistant, high clarity, can be made in a variety of colors |